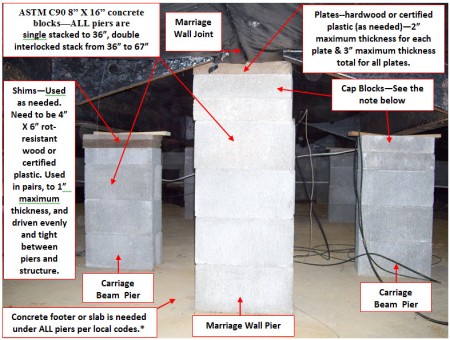

Directions for Typical Carriage and Marriage Wall Pier Construction

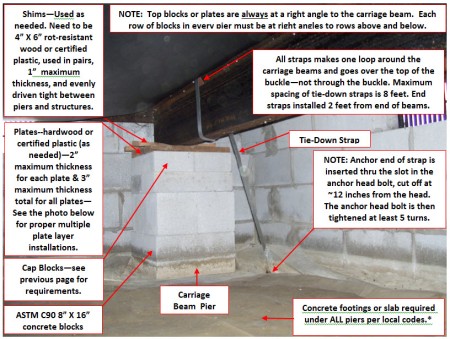

NOTE: Cap Blocks need to be 8” X 16” ASTM C145 concrete or 2” minimum thickness hardwood blocks on ALL piers. Other materials may be permitted EXCEPT 2” thick concrete blocks, which are NOT allowed as cap blocks or plates because they crack easily. An inspector may allow 2” blocks to be used lower in the pier stack; but be sure to check first with your inspector. Fully mortared piers should not require cap blocks.

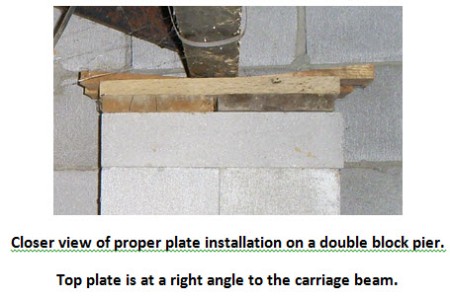

ALSO NOTE: ALL piers are installed at a right angle to the carriage beams and marriage wall and need to be centered under the carriage beams or marriage wall. Pier blocks need to be within ½” of plumb. Piers at the ends of each carriage beam need to be within 24 inches of the end of the beams.

Rechecking the level of the home and tightness of the piers after shimming all piers the first time is highly recommended. Leveling the home in one area may throw off the level in another. The level of newly set homes and tightness of its piers should also be checked after about six months and a year because the slab or footings could have settled. A recheck should also be done if the home develops cracks in the drywall, doors or windows that do not open or close as before, or gaps in places where they were not present before.

Directions for Double Stack Carriage Beam Piers And Tie-Down Straps

*Some

locations permit use of ABS pads. I do not support use of them without

proper soil testing or strict installation according to the

manufacturer’s

instructions, both of which are rarely done. So, in general, I don’t

support their use. This is my document; so it follows my rules.

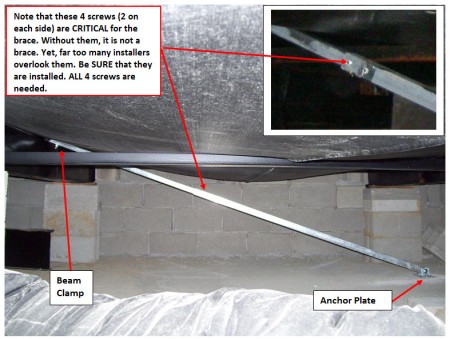

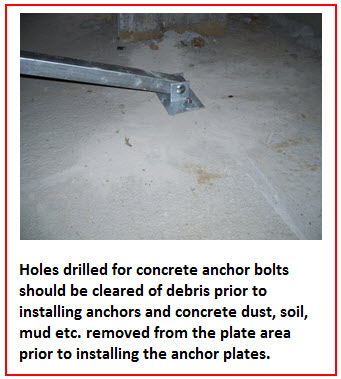

Directions for lateral brace installation

NOTES:

These photos show only one manufacturer’s lateral brace. Other manufacturers have slight variations.

Be sure to read and follow the manufacturer’s instructions for the particular brace being used.

The brace should not be bent or cut unless listed in the instructions.

No other beam clamp should be used or even manufactured for use with a particular manufacturer’s brace.

Yes, I have seen all of these cases.

Most lateral brace manufacturers require tie down straps at the corners of single-wide homes.

At least two braces are required for each home—located near opposite corners of the home and installed in opposing directions.

Homes over 76’ box length may need more braces.

Be sure to check the brace manufacturer’s installation instructions.

A PDF version of this document may be obtained by contacting:

Criterium-Cincinnati Engineers

criterium-cincinnati@fuse.net

513-474-9600

No comments:

Post a Comment