Overview:

This document discusses the proper methods (and more than one exists) for anchoring manufactured and modular homes with perimeter support foundations, which will be better defined just a little further on. The subject of this document is primarily proper anchoring methods because I frequently find mistakes in these anchoring systems. In my internet searches, I have not come across other publications that specifically address this topic. Building codes and other regulations, such as the Housing and Urban Development's model regulations, and manufacturer installation instructions describe or dictate construction of other foundation elements and the installation of the home; but details on anchoring requirements for these foundation systems is sketchy.

Therefore, I wrote this document to summarize the anchoring methods, and errors in anchoring methods, that I have found while performing over 500 FHA or other inspections on these homes (and all of the photos in this document came from those inspections). This document covers both manufactured and modular homes because some of the home constructions have very similar foundation and anchoring systems. Although Criterium-Cincinnati Engineers does not get many calls for modular home inspections, those I have inspected leads me to believe that the prevalence in anchoring issues are similar to those for manufactured homes.

Note that this article and its contents are only intended as guidance. It is not intended to be used as a design document or to replace any building codes or other applicable rules. Be sure to check local and state building code or other state installation rules for specific installation requirements.

General Guidance for Manufactured and Modular Home Foundation Systems:

Manufactured and modular homes mainly differ visually in that manufactured homes arrive on-site on their own wheels while modular homes are transported on-site via another carrier, such as a flat-bed trailer. For a more detailed description of differences, refer to these web sites:

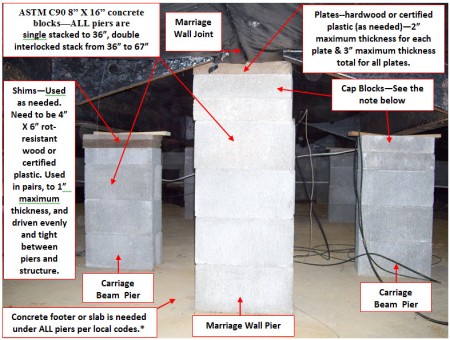

The majority of the manufactured and modular homes have pier (rather than perimeter) foundation systems. Photo 1 shows a typical pier system.

Photo 1. Typical manufactured home pier system.

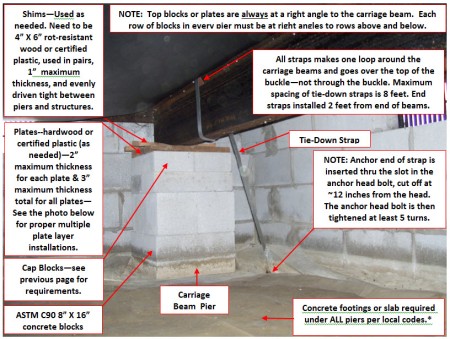

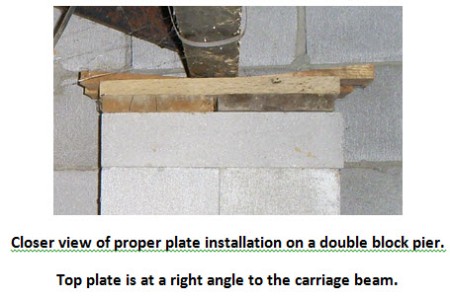

This foundation system uses piers, commonly constructed from concrete blocks (seen in the photo above) for the foundation system. The piers are supposed to be erected on either poured concrete footings or slabs For manufactured and on-frame modular homes that have I-beam structural members that are part of the home structure, the piers are located under and support the I-beams. (For manufactured homes, these beams are commonly called carriage beams because they are used to transport the home to the site. To use common terminology for both manufactured and modular homes, I use "home structural beams" in this document.)

Vinyl skirting or a concrete block perimeter wall is usually installed around underside of the perimeter of the home to enclose the pier foundation system. This skirting or perimeter wall is not part of the foundation system and is not structural. Skirting and perimeter walls have purpose, though, in that they help keep water and vermin from getting under the home, help protect the plumbing from freezing and prevent wind (more particularly high winds) from getting under and lifting the home.

Manufactured homes come in both single and doublewide constructions, while modular homes are usually doublewide construction. Singlewide means that the home is a complete home, constructed so that it can be moved into place as a unit and set on the foundation system. Doublewide structures arrive on-site in two halves that are moved together on a foundation system and the halves are then screwed together. Each half of the doublewide home comes with a hinged roof. Once the two halves of a doublewide are assembled, the roof is rotated into position and assembled. Although not yet common, complex manufactured and modular homes, such as multiple story structures, are being built. Foundation systems for the more complex structures are similar to the single-story structures, although adjusted for the extra weight.

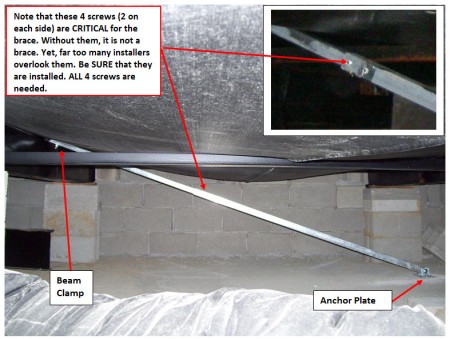

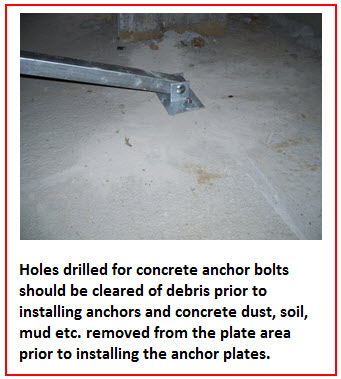

Both single and double-wide homes would have piers under the home structural beams, while a double-wide home would also have additional piers supporting points along the home's marriage line, as specified by the manufacturer. (The marriage line, which is sometimes also known as the mating line, is where the two halves of a double-wide home meet.) The anchoring systems for pier foundations for manufactured and on-frame modular homes is either a lateral brace system or steel straps with concrete or ground anchors, which are shown in Photos 2 and 3, respectively.

Photo 2. An example of one manufacturer's lateral brace anchored to a concrete slab.

This article, though, is about anchoring manufactured and modular homes that have perimeter foundation systems. The terminology "perimeter foundation system" might inspire a mind picture of the typical site-built home foundation system where the perimeter of the home is supported directly on the foundation system. Some manufactured and modular home foundation systems are similar to site-built home foundation systems, and they are discussed later in this article. However, most manufactured and on-frame modular homes with perimeter foundation systems are supported on H or I-beams that are in turn supported on the perimeter foundation system. In this article, these beams are called foundation beams (and can be seen in the photo below). Homes with foundation beams have different anchoring requirements than homes without foundation beams, and the former are discussed first. A typical foundation beam installation is shown in the Photo 4.

Photo 3. An example of one manufacturer's steel strap anchored to a concrete slab.

As the photos throughout this article show, perimeter foundation systems can be used for either basement or crawlspace foundations. Normally, though, foundation systems with center-support steel columns are used in homes with basements to allow for possible finishing of the basement. Basements and crawlspaces could have either gravel or concrete slab floors; but all should have footings installed under the center support columns or piers.

Manufactured and modular home perimeter foundations are constructed from either poured concrete or concrete block, similar to site-built homes. Local building codes usually dictate how foundations should be constructed. If the area has no local building codes, construction usually has to adhere to state building codes, which are usually a derivation of the International Building Codes (although the state's current building codes might not be as current as the International Building Codes). Homes installed in areas under the jurisdiction of a building department usually need to have a building department permit and at least a foundation system inspection. Further, installation permitting and inspection requirements can vary from state to state and even from area to area. Be sure to check local building code requirements specific to manufactured and modular homes. Concrete foundations usually have pockets built in the walls to support the ends of the foundation beams similar to the pockets installed in site-built home foundations to support the ends of these homes' main beams. Concrete block foundations usually have pilasters installed to support the beam ends, and the concrete blocks that comprise the pilasters need to have their holes completely filled with concrete. The concrete fill needs to have rebar reinforcement installed in the concrete. That being said, some concrete block foundations have pockets for the foundation beams instead of pilasters and some poured concrete foundations have pilasters for the foundation beams instead of pockets. Still, even if pockets are installed in a concrete block foundation, pilasters are still usually built in the foundation under the pockets and the blocks are filled with concrete with rebar reinforcement. Examples of foundation beam installations are shown in Photos 5 through 7.

Photo 4. An example of a manufactured home with a perimeter foundation system that uses foundation beams and concrete block center piers.

The ends of all structural beams for manufactured and on-frame modular homes need to be supported. In Photo 8, pilasters built next to the end foundation wall are used to support the structural beams. Other acceptable means for supporting the ends of the structural beams that I have found were pilasters built into the foundation walls, steel columns or foundation beams. Unlike the pilasters supporting the structural beams, concrete block columns do not have to be fully mortared, but must have proper cap blocks, which are usually half-filled 8-inch or 4-inch thick concrete blocks or 2-inch minimum hardwood boards that are at least the same dimensions as the pier blocks. Piers and steel columns need to have proper footings. If foundation beams, piers or steel columns are used instead of pilasters to support the ends of the home structural beams, they need to be located within 2 feet of the ends of the home structural beams.

Photo 5. Example of a foundation beam installed in a pocket on top of a pilaster in a concrete block foundation wall.

Photo 6. Example of a foundation beam installed on a pilaster of a concrete block foundation without a pocket.

Photo 7. Example of a foundation beam installed in a pocket in a poured concrete foundation wall.

Photo 8. An example of piers supporting a manufactured home's structural beams.

Photo 9. An example of shimming for the end of a home structural beam.

As Photo 9 shows, the ends of the structural beams may need shimming. While the home's structural beams are shimmed, the foundation beams are not normally shimmed. When wood shims are used, they need to be a minimum 4-inch wide hardwood and used in pairs, as shown in the photo. Shims are not usually used between the foundation or pilasters and the foundation beams. The reason is that the home is usually leveled by installing shims between the foundation beams and the home structural beams because adjustment needed between one foundation beam/structural beam contact point and another can vary significantly. Shims are also sometimes used between the middle support piers and the foundation beams. The proper shims between the home structural and foundation beams will be discussed in more detail later in this article. But the shims between the middle support piers and the foundation beams are a minimum 4-inch wide hardwood and used in pairs

As Photos 4 and 10 show, the foundation beams are located in nearly the same locations as would be the piers for a pier foundation home. That is, steel beams run the width of the home in similar locations to the piers and support the home's structural beams and marriage line (if needed) in the same way as the piers. The ends of the foundation beams are supported on the home's front and rear perimeter walls.

Photo 10. An example of a perimeter foundation system that uses foundation beams and center support columns.

Double-wide homes usually have either concrete block piers or steel columns supporting the center of the foundation beams. Photo 10 shows an example of steel columns while Photo 11 shows an example of concrete block piers. Columns need to be fastened at the bottom to the footing or slab and at the top to the foundation beam or other marriage line structure, which will be discussed later. These fastening requirements hold true for other locations steel piers might be used, such as at the ends of the home structural beams.

Depending on the manufacturer requirements, extra piers may be needed to support the marriage line at other locations other than above the foundation beams, as shown in the Photo 11. Installation instructions usually show where marriage line piers are needed. For newer homes, most manufacturers indicate where support is needed along the marriage line with some kind of mark on the bottom board (the membrane covering the underside of the home). If the manufacturer calls for support of the marriage line at a point less than 2 feet from a foundation beam, then additional support may not be needed.

I have been asked whether piers have to be unmortared (a.k.a. dry-stacked) or mortared. Mortaring is required in Housing and Urban Development (HUD) 7487. Permanent Foundations Guide for Manufactured Housing, the guidelines used for foundation inspections for Federal Housing Authority (FHA) loan approval. The latest HUD standard (24 CFR 3285. Model Manufactured Home Installation Standards) used as a model for current manufactured home installations does not require mortaring of any foundation pier blocks, including the marriage line piers, unless they are specially designed or in flood plains. This standard does require piers from 32 to 60 inches to be double-stacked, as shown in Photo 11, and piers over 60 inches to be designed by a licensed engineer or architect. Additionally, the standard requires that ALL piers for homes in flood plains be designed by a licensed engineer or architect and meet the requirements of the local flood plain authority. But, the standard provides no information for the piers used in perimeter foundation systems other than they are designed by a licensed engineer or architect or adhere to the manufacturer's installation instructions. I have found both mortared and unmortared marriage line and end support piers. I have also not found any issues with properly installed unmortared piers built on properly designed and installed footings.

Homes that have steel columns instead of piers may also need to have support for the marriage line that is farther than 2 feet from the foundation beams. In these cases, additional steel columns can be installed, or if a wall has been installed under the marriage line, for example as part of finishing a basement, the wall can be extended to the marriage line to provide support. However, that wall then becomes a load-bearing wall. Other methods can also be used to support the marriage line between foundation beams; but a licensed engineer or architect should be hired to specify such construction.

Double-wide homes also have blocking installed on top of the foundation beams above all center piers to support the marriage line. Foundation systems that use steel columns instead of piers to support the foundation beams also have blocking is installed on top of the foundation beams above the columns, as shown in Photo 12. Blocking is usually wood, although concrete blocks can also be used as long as a cap block is installed on top of the blocks, as visible in Photo 11. Blocking needs to be at least the width of the foundation beam flange and at least twice as long as wide to assure stability.

Gaps between the top of piers and blocking along the marriage line need to be shimmed. Shims need to be at least 4 inches wide, hardwood or equivalent and used in pairs. These shims need to be driven tight between the pier or blocking and the marriage line.

For information on the currently acceptable construction piers, please refer to 24 CFR 3285: MODEL MANUFACTURED HOME INSTALLATION STANDARD (

http://www.access.gpo.gov/nara/cfr/waisidx_08/24cfr3285_08.html) or your state's current installation standards (which should be a derivation of 24 CFR 3285). Keep in mind that these standards defer to the manufacturer's installation instructions, if available.

Installers should read and follow the manufacturer's installation instructions. Not following the manufacturer's instructions could void the home's warranty or the expose the installer or others to liability issues. The information presented in this article is not intended to replace the installation instructions.

Photo 11. Examples of concrete block piers under the marriage line and mid-point of the foundation beam.

Photo 12. Examples of marriage line support blocking and a steel column support under the mid-point of a foundation beam.

Anchoring Systems for Perimeter Foundation Systems:

To properly anchor manufactured and on-frame modular homes with perimeter foundations, the foundation beams need to be anchored to the foundation AND the home structural beams need to be fastened to the foundation beams supporting them. This latter part of the anchoring system seems to be most often forgotten or unknown. No one method exists for anchoring the foundation beams to the foundation; but the anchoring method needs to meet these basic criteria:

- BOTH ends of all foundation beams need to be anchored to the foundation.

- If the foundation beam ends are not located in pockets that are tight enough to prevent twisting or sideways movement of the beams, both sides of each end of the foundation beams need to be anchored or the full widths of the beams have to be anchored (as shown in the example photos later in this article).

- The anchors have to prevent the foundation beams from being pulled laterally out of the pockets or off the pilasters, as could happen if the foundation wall moves outward.

- The anchors have to prevent the foundation beams from being pushed sideways off of the pilasters.

- The anchors or the foundation pockets have to prevent the ends of the foundation beams from being lifted vertically off of the pilasters or within the pockets.

Manufactured and on-frame modular homes installed on poured concrete foundations have more anchoring options than concrete block foundations because anchors for the latter need to be tied to the reinforcement in the concrete-filled blocks in the foundation. Photos in this section show examples of a variety of anchoring methods that I have found during inspections of manufactured homes with foundation beams.

Photo 13 shows the end of a foundation beam on top of a pilaster. By far the most common method for anchoring foundation beams to concrete block foundations is using the rebar installed to reinforce the pilaster. As shown, the rebar is extended above the pilaster, and bent over onto and welded to the foundation beam, as shown in the photo. This photo shows the preferred method for attaching the rebar to the beam in that the rebar ends are kept short and at least 2 inches of the rebar is welded solidly to the beam (indicated by the arrow). A similar rebar anchor is on the other side of the beam to prevent the beam from moving sideways on the pilaster. Both sides of each rebar end should be welded to the beam.

Photo 14 shows another variation of a rebar anchor that is acceptable, although not as ideal as the previous photo. In this installation, a similar rebar anchor was installed on the other side of the beam. This anchor would be more ideal if the area around the base of the rebar inside the block were mortared to stiffen the rebar.

Photo 15 shows another rebar/beam anchor that is not acceptable. As this photo shows, the rebar is much longer than those shown in Photos 13 and 14. Although the longer rebar means that it can be bent into position more easily, the longer rebar does not restrain the beam from excessive movement. Furthermore, only the very end of the rebar is welded, which could allow the rebar to break loose if the beam moved. A closer pocket around the beam would restrict the beam from moving sideways; but the excessive length of the rebar would not prevent is from being pulled from the pocket. This anchor could be fixed by shortening the rebar on both sides of the beam and welding at least 2 inches of the rebar to the beam.

Photo 13. Example of pilaster rebar being used also as an anchor for a foundation beam.

Photo 14. Another example of pilaster rebar also being used to anchor a foundation beam.

:

Photo 15. Example of pilaster rebar being used improperly as an anchor for a foundation beam.

Improper welding of the rebar is a common issue with the rebar anchor, as shown in the Photo 15. If enough off the rebar is not welded to the foundation beam, the weld can break loose, as indicated by the arrow Photo 16. In this case, the installer apparently tack welded the rebar and the weld had later broken loose simply by the rebar pulling upward on the weld. If the weld could break loose simply due to the rebar force, imagine the rebar trying to prevent the beam from moving. As with the case shown in Photo 15, to fix this issue, the rebar should be shortened first and at least 2 inches of the rebar welded the beam.

Photo 17 shows a gross misuse of a rebar anchor. As the photo below shows, the rebar is run from the foundation footing to the foundation beam. Obviously, this anchor would not constrain movement of the foundation beam and would therefore not be an acceptable anchor. This photo also shows another issue with the pilaster construction. Gaps in the mortar show that the blocks were not fully mortared, nor filled with concrete or reinforced with rebar.. At least, this installer used a sold 4-inch concrete block on top of the pilaster to properly transfer the beam load fully across the pilaster.

Photo 16. Another example of an improper rebar anchor; but in this case, the rebar has pulled loose due to not being welded properly.

Photo 17. Another example of an improper rebar anchor for a foundation beam. Also shown is an example of an improperly constructed pilaster.

As stated previously, poured concrete foundations offer additional anchoring options as shown in the following Photos 18 and 19.

Photo 18. Example of a proper foundation beam anchor using angle iron that has been bolted to foundation and welded to the foundation beam.

Photos 18 and 19 show two variations of the same type of anchor, except one was installed under the foundation beam and the other over the foundation beam. Both photos show that the anchor is bolted solidly to the foundation and both are wider than the beam flanges. The foundation beams need to be welded fully to the anchors, as can be seen clearly in Photo 19. Even if the anchor is installed above the beam, welding is needed to prevent the beam from being pulled upward or out of the pocket. Note also that the beam pockets in both photos are just wide enough to accommodate the beam, which helps prevent beam twist. However, these types of anchors should also help prevent twist.

Photo 20 shows a clever use of tie-down straps normally used to anchor homes on pier foundation systems. In this case, the straps normally used to fasten piered home's structural beams to a concrete footing or pad have been used to anchor this home's structural beams the concrete foundation. Further, the strap has been properly looped around the carriage beam according to the manufacturer's instructions, which firmly secures the strap buckle to the home structural beam. Many installers do not properly install these straps. The additional strap between the carriage beam and the end foundation wall should not be needed because the home structural beam's movement is constrained by the foundation and other anchors; but the manufacturer's installation instructions should be followed to prevent voiding warranties. Nonetheless, this installation does not meet the overall guidelines stated earlier because the foundation beams have not been anchored to the foundation or the structural beams have not been fastened to the foundation beams. Note also that this photo shows an example of an installation with a foundation beam installed near the end of the home structural beams instead of a pilaster, pier or column.

Photo 19. Example of another proper anchoring method using angle iron bolted to foundation.

Photo 20. Example of an anchor method using steel strap anchors attached to the foundation.

In some cases, concrete block is sometimes installed on top of a poured concrete foundation. This kind of change can happen if additional headroom in a basement was desired after the concrete foundation has already been poured. Photo 21 shows the way one installer, almost acceptably resolved this issue. The installer built pockets in the block to constrain the foundation beams and then welded angle anchors to the beams that extended to the poured concrete foundation. However, the installer did not bolt the angles to the foundation, making this installation not acceptable. The installer also did reinforce the concrete blocks surrounding the foundation beams by installing rebar that was anchored into the concrete foundation and filling the block holes with concrete. In fact, I believe that the designer should have specified that all of the concrete block sections be reinforced and concreted.

Photo 21. Example of a possible proper foundation beam anchor used on a mixed materials foundation. However, the angle section needs to be bolted to the foundation.

To complete a proper anchoring system for foundation beam systems, the home structural beams need to be fastened to the foundation beams. Manufacturer installation instructions that I have reviewed require that the structural beams be fastened to the foundation beams at ALL points where they cross. Manufacturers usually allow two fastening methods, either 1/4"-inch fillet welds or bolting. An example of welding is shown in Photo 22 and bolting in Photo 23.

Photo 22. Example of a proper welding between a structural beam and foundation beam.

Photo 23. Example of a bolt fastening a structural beam to a foundation beam.

By far, welding is usually more expedient than bolting and more secure. Installers considering bolting should check with the manufacturer to assure that drilling holes in the home structural beams will not void the home's warranty. If bolting is allowed, installers should also check for the manufacturer's specifications for bolt size and torque. Installers should also verify whether washers and lock nuts are needed. Installation instructions for welding usually require that both sides of either the home structural or foundation beam be welded; but installers should follow the manufacturer's specific instructions for the home. Installation instructions also normally require that each joint be fully welded across the full width of the structural or foundation beam, as shown in Photo 22. A number of installers us a weld of only 1 or 2 inches, which is normally not acceptable. Alternative methods of fastening the two beams together may exist; but the installer should check with the manufacturer for acceptability. In the absence of installation instructions, installers should follow local building codes requirements for fastening the beams together.

Earlier in this article, I noted that shims are normally installed between the foundation beams and home structural beams rather than between the foundation beams and the foundation. Wood shims, as shown in Photo 24, are not acceptable because they may not support the load and they do not allow proper fastening of the foundation beams to the home structural beams. Additionally, when joints with shims are welded, the shim needs to be fully included in the weld, as shown in Photo 25.

Photo 24. Improper use of wood shims between a foundation beam and structural beam.

Photo 25. Proper welding of the metal shims used between a structural beam and foundation beam.

Alternative Foundation Systems and Anchoring Methods:

Previously, I mentioned a second general type of manufactured and modular home construction that is supported directly on the perimeter foundations without need for foundation. From the underside, these homes look very similar to site-built homes, as can be seen in the Photos 26 through 28. The first two photos are manufactured homes and the last photo is a modular home. The marriage line of these homes are usually supported on steel columns or concrete block piers. A load-bearing wall could also be used instead of columns; but, the homes I have inspected that had frame walls built under the marriage line also usually had steel columns. If a frame wall is planned to be used as a load-bearing wall instead of steel columns, consult the manufacturer's installation instructions or local building codes to verify that load-bearing wall construction is acceptable.

Note that in Photos 26 through 28 the marriage line is the equivalent of the main beam in a site-built home, except one-half of the marriage line "beam" belongs to each side of the home. The two halves are screwed together when the homes are mated together. These homes come in a variety of constructions, and manufacturers are likely to make changes in the future to make the homes look even more like site-built homes.

Another difference between these homes and those with foundation beams is that these homes are anchored around the perimeter to a sole plate that sits on top of the foundation. To fully anchor these homes, the sole plate must be anchored to the foundation AND the home needs to be anchored to the sole plate.

Photo 26. Example of one style of manufactured home that uses perimeter anchoring to a sole plate instead of foundation beams.

Photo 27. Another example one style of manufactured home that uses perimeter anchoring to a sole plate instead of foundation beams.

Photo 28. Example of one style of modular home that uses perimeter anchoring to a sole plate instead of foundation beams.

Two methods for anchoring the sole plate are shown in the following Photos 29 and 30. Photo 29 shows a sole plate anchored to the foundation using an anchor bolt while Photo 30 shows a sole plate attached to the foundation using metal straps fastened to the foundation. Some installers have also used concrete anchors and bolts to fasten the sole plate to the foundation. Local or state building codes, the International Building Code or the manufacturer instructions should be consulted to determine acceptable methods for how the sole plate is fastened to the foundation. Keep in mind that the weaker the fastening method, the more anchors might be needed. For example, I would expect fewer anchors being needed for the anchor bolt fasteners in Photo 29 than the strap anchors in Photo 30.

I have observed two variations in home construction that determine how the home is anchored to the sole plate. For homes with wood joists, the joists can be fastened to the sole plate directly, as shown in Photo 31. In this installation, the sole plate was oversized and lag screws were used to screw joists to the sole plate.

Homes with steel joists may have a sole plate attached to the bottom of the joists, as shown in the Photo 32. As can be seen in this photo, this sole plate is then screwed to the foundation sole plate.

Photo 29. Example of a sole plate bolted to the foundation. The home is then fastened to the sole plate.

Photo 30. Example of a strap anchor being used to anchor a sole plate to foundation.

Photo 31. Example of a home joist being screwed to the sole plate to complete the anchoring system.

Photo 32. Example of a manufactured home bolted to a sole plate.

Some homes have band joists that extend below the floor joists, which can be seen as oriented strand board in Photo 29. For these homes, the band joist can be fastened to the sole plate from the exterior side of the rim joist prior to siding being installed over the band joist. On the other hand, some manufacturers extend the exterior sheathing below the floor level and attach the joists to the sheathing, which appears to be the case in Photo 30. Manufacturers may have specified methods for anchoring the home in the installation instructions. If the instructions do not specify an anchoring method, refer to local or state building codes or contact the manufacturer or a licensed engineer or architect for recommendations.

Although manufacturers might allow anchoring the home using the rim joist or exterior sheathing, I do not favor this method of anchoring. One major issue with this anchoring method is that a gap is sometimes left between the exterior sheathing or band joist and the sole plate because of an error or inaccuracy in construction. This gap could be sizeable. For one home I inspected, a gap of nearly 1 inch was present in some places around the home's perimeter. The strength in this anchoring method comes mainly from the contact between the sheathing or band joist and the sole plate woods when the fastener pulls them together. If a gap is present, the fasteners take the entire load, which weakens the anchor. Additionally, verifying whether the home has been properly anchored is difficult to impossible once the siding has been installed. Due to the number of issues with this method of anchoring the home, I recommend that an alternate method that anchors the home's joists to the sole plate be used if possible.

The Wrap:

I have tried to be as thorough as possible in writing this article; however, I have likely missed some important points. Further, manufacturers periodically change designs that could change installation requirements. Further, so much variation exists currently in home designs that a particular home's foundation system and anchoring method may be different than presented in this article; but those in this article may still be acceptable.

Another important point is that recent HUD rules require states to develop installation rules based on the HUD model standards (24 CFR 3285). HUD further required that new manufactured home sets be inspected according to each state's rules. For installations not covered in the HUD or state rules, such as perimeter foundation systems, HUD rules and likely many state rules defer to the manufacturer's installation instructions or specifications by a licensed engineer or architect designs. If other state rules are similar to those in Ohio, this information must be obtained prior to obtaining a permit to begin construction. Make sure you are aware of your state's requirements so that a potentially stiff fine or reconstruction costs are avoided.

Please be sure to contact us with questions or comments or to request a PDF version of this article. I hope to revise this article based on those comments and questions.